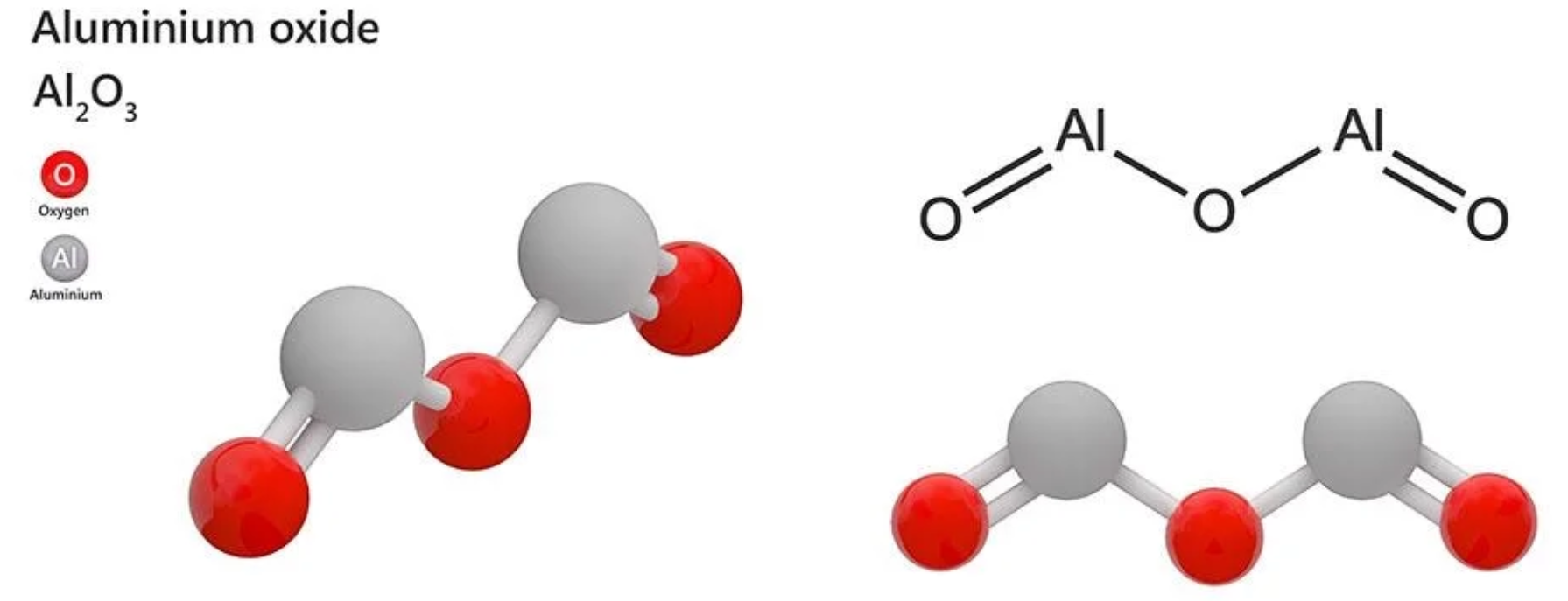

♦Alumina(Al2O3)

O vaega sima sa'o na gaosia e le ZhongHui Intelligent Manufacturing Group(ZHHIMG) e mafai ona faia i mea fa'amea ma'a maualuga, 92 ~ 97% alumina, 99.5% alumina,> 99.9% alumina, ma le CIP malulu isostatic oomi. Sintering vevela maualuga ma machining saʻo, saʻo saʻo o le ± 0.001mm, lamolemole e oʻo atu i le Ra0.1, faʻaaoga le vevela e oʻo atu i le 1600 tikeri. O lanu eseese o ceramics e mafai ona faia e tusa ai ma manaoga o tagata faatau, e pei o le: uliuli, paepae, beige, lanu mumu, ma isi O vaega sima saʻo gaosia e la tatou kamupani e tetee i le vevela maualuga, corrosion, ofuina ma insulation, ma e mafai ona faaaogaina mo se taimi umi i le vevela maualuga, gaogao ma corrosive siosiomaga kesi.

Fa'aaoga lautele i le tele o masini gaosiga o le semiconductor: Fa'avaa (fa'ama'i sima), Substrate (fa'avae), Arm/ Bridge(manipulator), , Mechanical Components ma Ceramic Air Bearing.

| Igoa Oloa | Mama maualuga 99 Alumina Ceramic Square Tube / Pipe / Rod | |||||

| Fa'asinomaga | Vaega | 85 % Al2O3 | 95 % Al2O3 | 99 % Al2O3 | 99.5 % Al2O3 | |

| Malosi | g/cm3 | 3.3 | 3.65 | 3.8 | 3.9 | |

| Suavai | % | <0.1 | <0.1 | 0 | 0 | |

| Tempered Sintered | ℃ | 1620 | 1650 | 1800 | 1800 | |

| Malosi | Mohs | 7 | 9 | 9 | 9 | |

| Malosi punou(20℃)) | Mpa | 200 | 300 | 340 | 360 | |

| Malosi Compressive | Kgf/cm2 | 10000 | 25000 | 30000 | 30000 | |

| Taimi umi Galulue Vevela | ℃ | 1350 | 1400 | 1600 | 1650 | |

| Max. Galulue Vevela | ℃ | 1450 | 1600 | 1800 | 1800 | |

| Volume Resistivity | 20℃ | Ω. cm3 | >1013 | >1013 | >1013 | >1013 |

| 100℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300℃ | >109 | >1010 | >1012 | >1012 | ||

Faʻaaogaina o le maualuga o le mama alumina ceramics:

1. Faʻaaogaina i masini semiconductor: ceramic vacuum chuck, tipi tipi, faʻamama tisiketi, ceramic CHUCK.

2. Fa'aliliuina vaega o le wafer: chucks fa'afefeteina, tisiki tipi tipi, tisiketi fufulu mama, ipu suction suction su'esu'e.

3. LED / LCD mafolafola fale fa'aali alamanuia: pusi sima, tisiki olo sima, PIN SI'I, PIN nofoaafi.

4. Feso'ota'iga fa'apitoa, alamanuia o le la: paipa sima, to'oto'o sima, laupapa va'aiga lau lomitusi sima sima.

5. Fa'asa'o vevela ma vaega fa'a'ese'ese eletise: pa'u sima.

I le taimi nei, e mafai ona vaevaeina ceramics alumini oxide i le mama maualuga ma ceramics masani. O le maualuga mama alumini oxide ceramics faasologa e faasino i mea sima o loʻo i ai le sili atu i le 99.9% Al₂O₃. Ona o lona vevela vevela e oʻo atu i le 1650 - 1990 ° C ma lona umi o le galu o le 1 ~ 6μm, e masani lava ona gaosia i tioata fused nai lo le platinum crucible: lea e mafai ona faʻaaogaina e pei o le sodium tube ona o lona faʻamalamalamaina o le malamalama ma le faʻaleagaina o le alkali. I totonu o le alamanuia faaeletonika, e mafai ona faʻaaogaina e avea ma mea faʻapipiʻi faʻasolosolo maualuga mo mea faʻapipiʻi IC. E tusa ai ma mataupu eseese o le alumini oxide, o le masani alumini oxide sima faasologa e mafai ona vaevaeina i 99 ceramics, 95 ceramics, 90 ceramics ma 85 ceramics. O nisi taimi, o sima ma le 80% poʻo le 75% o le alumini oxide o loʻo faʻavasegaina foʻi o se faʻasologa masani o le alumini oxide. Faatasi ai ma i latou, 99 alumini oxide mea sima o loʻo faʻaaogaina e gaosia ai le vevela maualuga, faʻamau afi afi ma mea faʻapitoa faʻaofuofu, e pei o paʻu sima, faʻamaufaʻailoga sima ma ipu valve. 95 alumini ceramics e masani ona faʻaaogaina e avea ma vaega e teteʻe ai i le ofuina. 85 ceramics e masani ona faʻafefiloi i nisi o meatotino, ma faʻaleleia atili ai le eletise ma le malosi faʻainisinia. E mafai ona faʻaaogaina molybdenum, niobium, tantalum ma isi faʻamaufaʻailoga uʻamea, ma o nisi e faʻaaogaina e pei o masini eletise eletise.

| Mea'ai Tulaga (Fa'atusa Tau) | Igoa Oloa | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Fa'ainumera Fa'ainumera Low-Sodium Easy Sintering Product | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Lol | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Medium Particle Diameter (MT-3300, metotia su'esu'e leisa) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| α Tele tioata | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Fausia le Density** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Malosi o le Sintering** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Fa'aiti'itia le fua o le Laina Sintering** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO e le o aofia i le fuafuaina o le mama o Al₂O₃.

* Leai se pa'u fua 29.4MPa (300kg/cm²), o le vevela o le sintering e 1600°C.

AES-11 / 11C / 11F: Faʻaopoopo 0.05 ~ 0.1% MgO, o le sinterability e sili ona lelei, o lea e faʻaoga i le alumini oxide ceramics ma le mama o le sili atu i le 99%.

AES-22S: Faʻaalia i le maualuga o le faʻapipiʻiina ma le maualalo o le faʻaitiitia o le laina sintering, e faʻatatau i le faʻafefeina o le faʻailoga ma isi oloa tetele e manaʻomia le saʻo saʻo.

AES-23 / AES-31-03: O loʻo i ai se maualuga maualuga, thixotropy ma laʻititi laʻititi nai lo le AES-22S. o le muamua o loʻo faʻaaogaina i ceramics aʻo faʻaaogaina le mea mulimuli e fai ma vai faʻaitiitia mo mea e faʻafefe ai afi, maua le lauiloa.

♦Silicon Carbide (SiC) Uiga

| Uiga Lautele | Mama o vaega autu (wt%) | 97 | |

| Lanu | Lanu uliuli | ||

| Malosi (g/cm³) | 3.1 | ||

| Suavai mitiia (%) | 0 | ||

| Uiga Fa'ainisinia | Malosi fa'afoliga (MPa) | 400 | |

| Young modulus (GPa) | 400 | ||

| Malosi Vickers (GPa) | 20 | ||

| Uiga vevela | Maualuluga o galuega (°C) | 1600 | |

| Coefficient fa'alauteleina vevela | RT~500°C | 3.9 | |

| (1/°C x 10-6) | RT~800°C | 4.3 | |

| Fa'avevela vevela (W/m x K) | 130 110 | ||

| Tete'e te'i vevela ΔT (°C) | 300 | ||

| Uiga faaeletise | Tete'e o le voluma | 25°C | 3x106 |

| 300°C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Dielectric tumau | 10GHz | - | |

| Ga'i eletise (x 10-4) | - | ||

| Q Factor (x 104) | - | ||

| Volivili malepelepe fa'a eletise (KV/mm) | - | ||

♦Silicon Nitride Ceramic

| Meafaitino | Vaega | Si₃N₄ |

| Metotia Sintering | - | Fa'amama le kasa Sintered |

| Malosi | g/cm³ | 3.22 |

| Lanu | - | Efuefu Pogisa |

| Fua o le Suavai | % | 0 |

| Young Modulus | Gpa | 290 |

| Vickers Malosi | Gpa | 18 - 20 |

| Malosi Compressive | Mpa | 2200 |

| Malosi punou | Mpa | 650 |

| Amioga vevela | W/mK | 25 |

| Tete'e Te'i vevela | Δ (°C) | 450 - 650 |

| Mata'utia Fa'agaioiga Vevela | °C | 1200 |

| Volume Resistivity | Ω·cm | > 10 ^ 14 |

| Dielectric tumau | - | 8.2 |

| Malosiaga Dielectric | kV/mm | 16 |